Precision Capabilities

Providing customized solutions for any application, in any industry.

We have a large, modern fleet of machining equipment including the latest in fully automated CNC technology. Our capabilities range from round tooling to precision punches & dies. From engineering to production, The Producto Group has solutions to meet your most challenging needs.

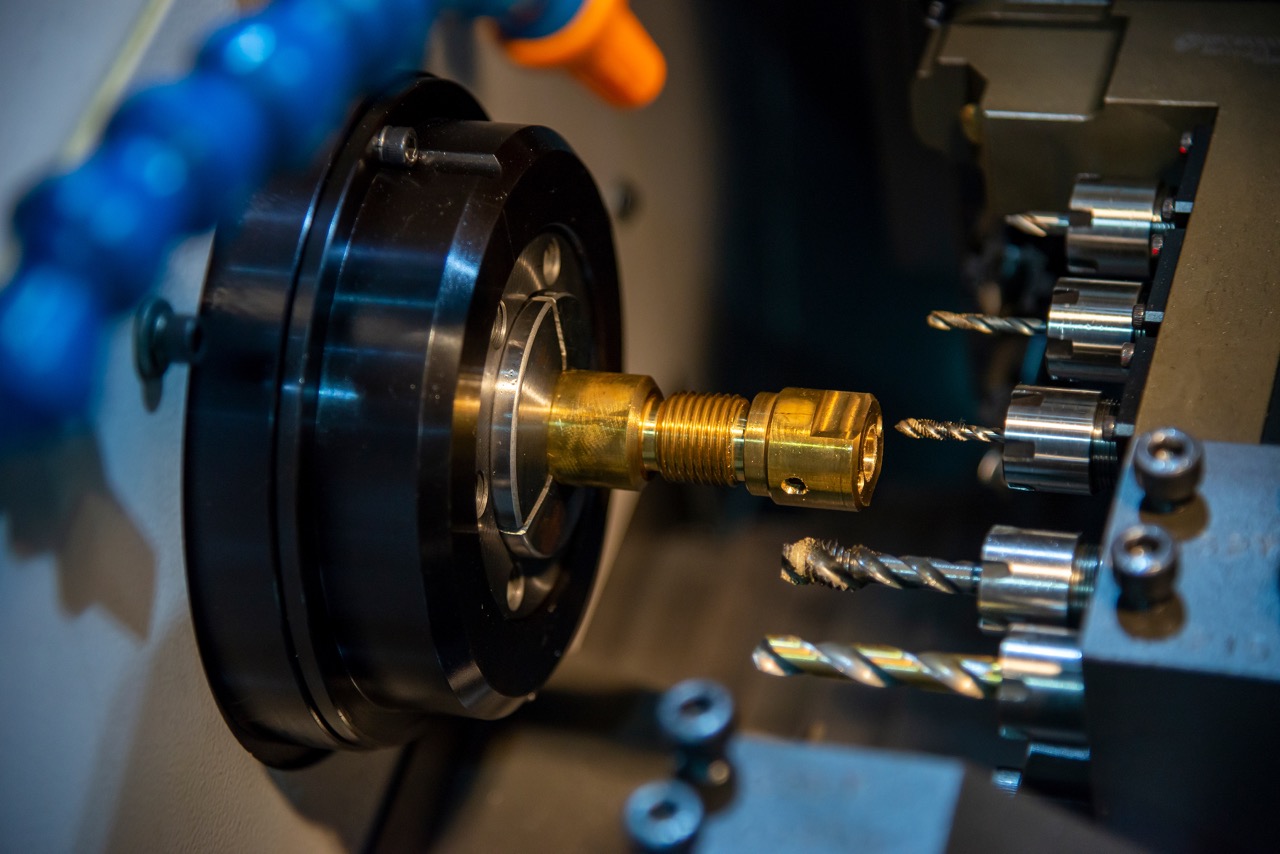

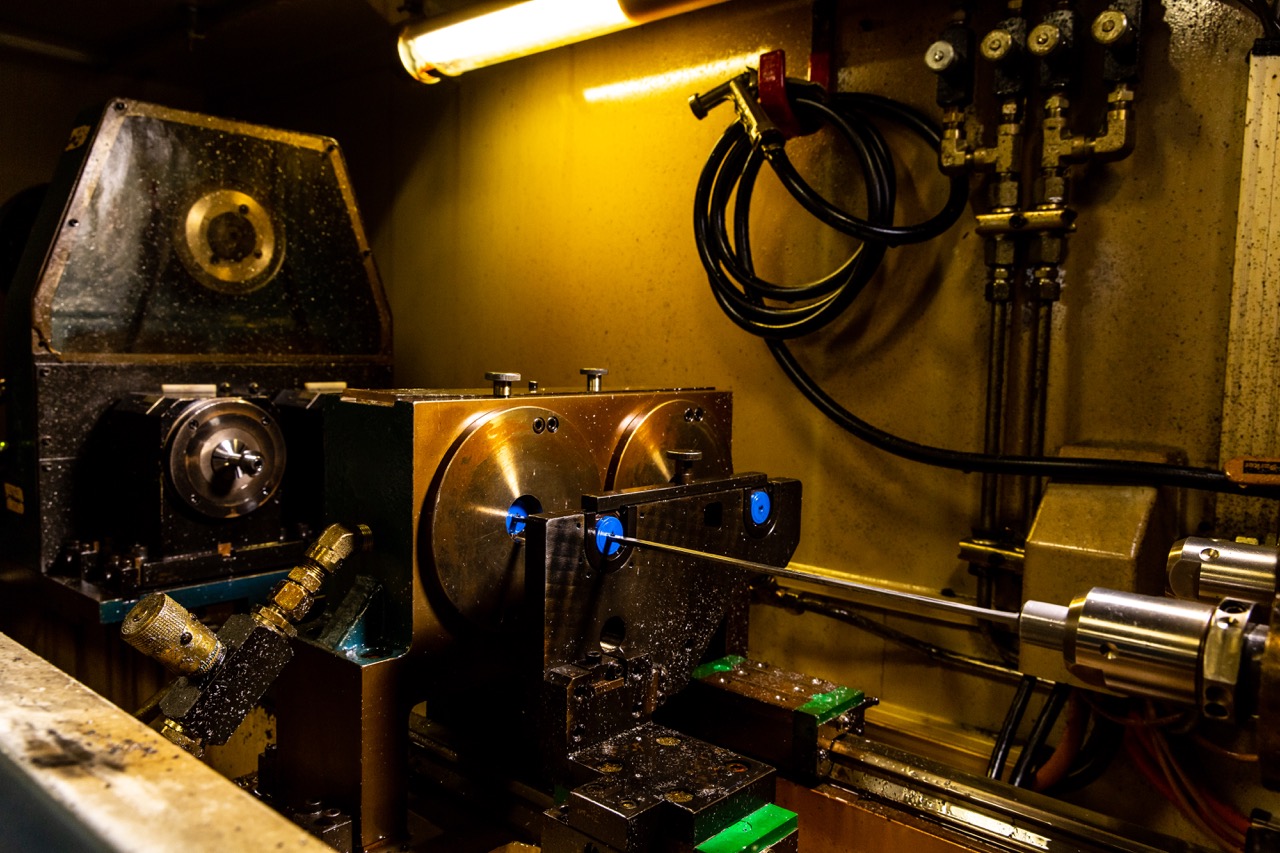

Precision Turning & Multi-Tasking

Swiss Lathe Turning

- Automatic Multi-Bar Raw Material Delivery, Part Length up to 20″

- 5 Axis Operation + Sub-Spindle Up To 38mm Diameter

- Balance-Cut (Pinch) Turning Capabilities Up To 38mm Diameter

- Capable of Achieving 16 RMS Precision Surface Finishes

- Concentricity to 0.001, Tolerances to 0.0005

- Part Diameter up to 1.5″

Explore our Producto Partner Solutions:

Precision Tooling

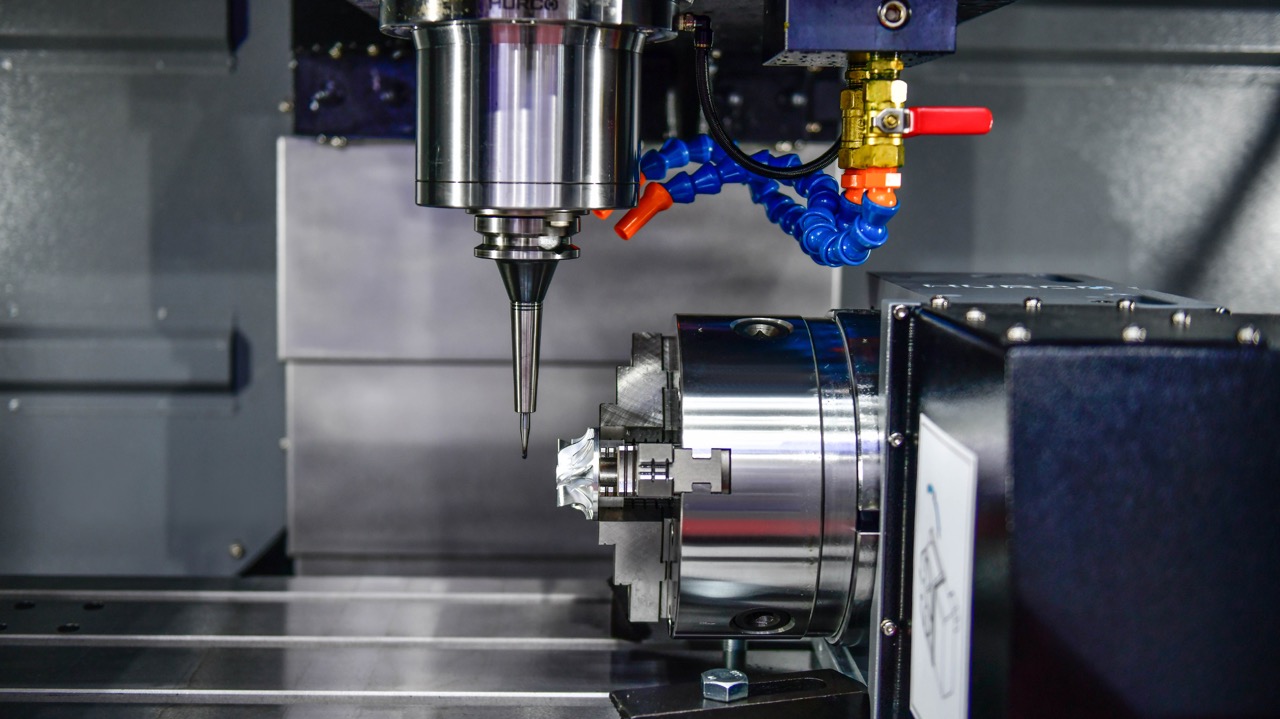

Precision CNC Machining

Precision Milling

-

- 5 Axis Milling of Materials up to 62 RC/Hardness

- Thermally Cooled Hard Mill Spindles

- Shrink Fit Tooling for Improved Accuracy

- Integrated Robots for Lights Out Operation

- Part Length up to 40″

- Capable of Achieving 12 RMS Precision Surface Finish

- Concentricity to 0.0004, Tolerances to 0.0004

Explore our Producto Partner Solutions:

Precision Tooling

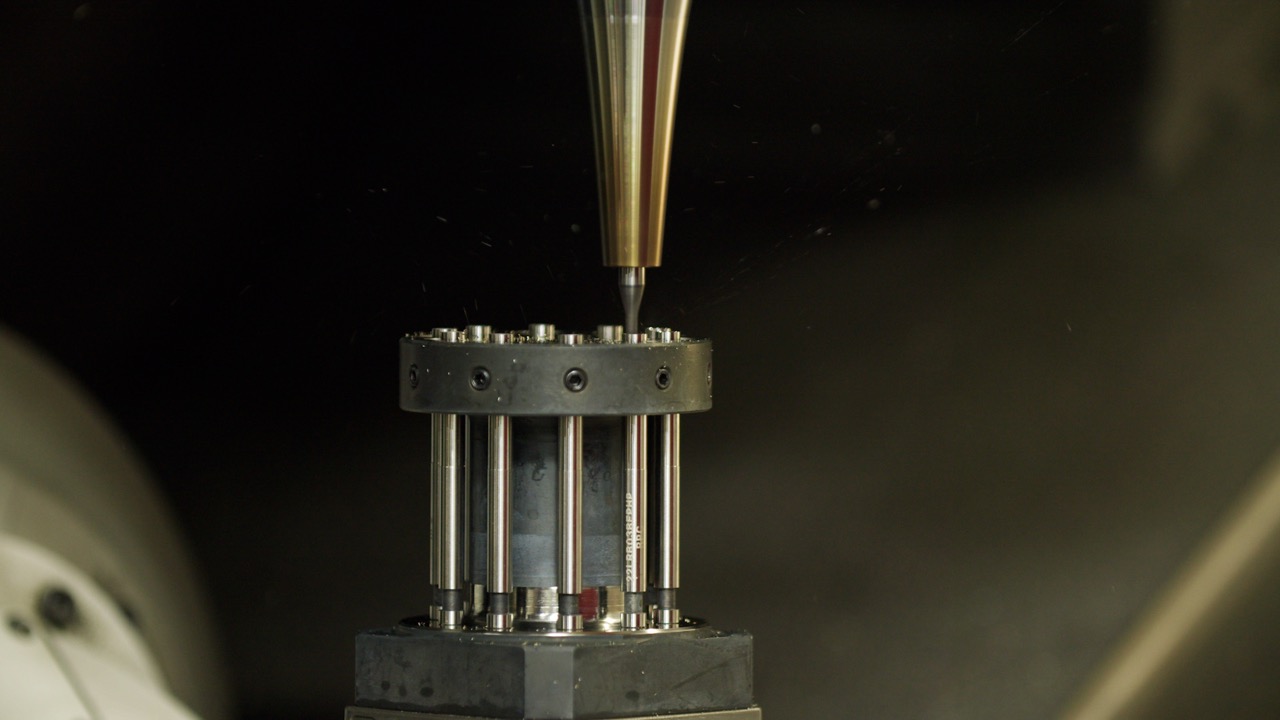

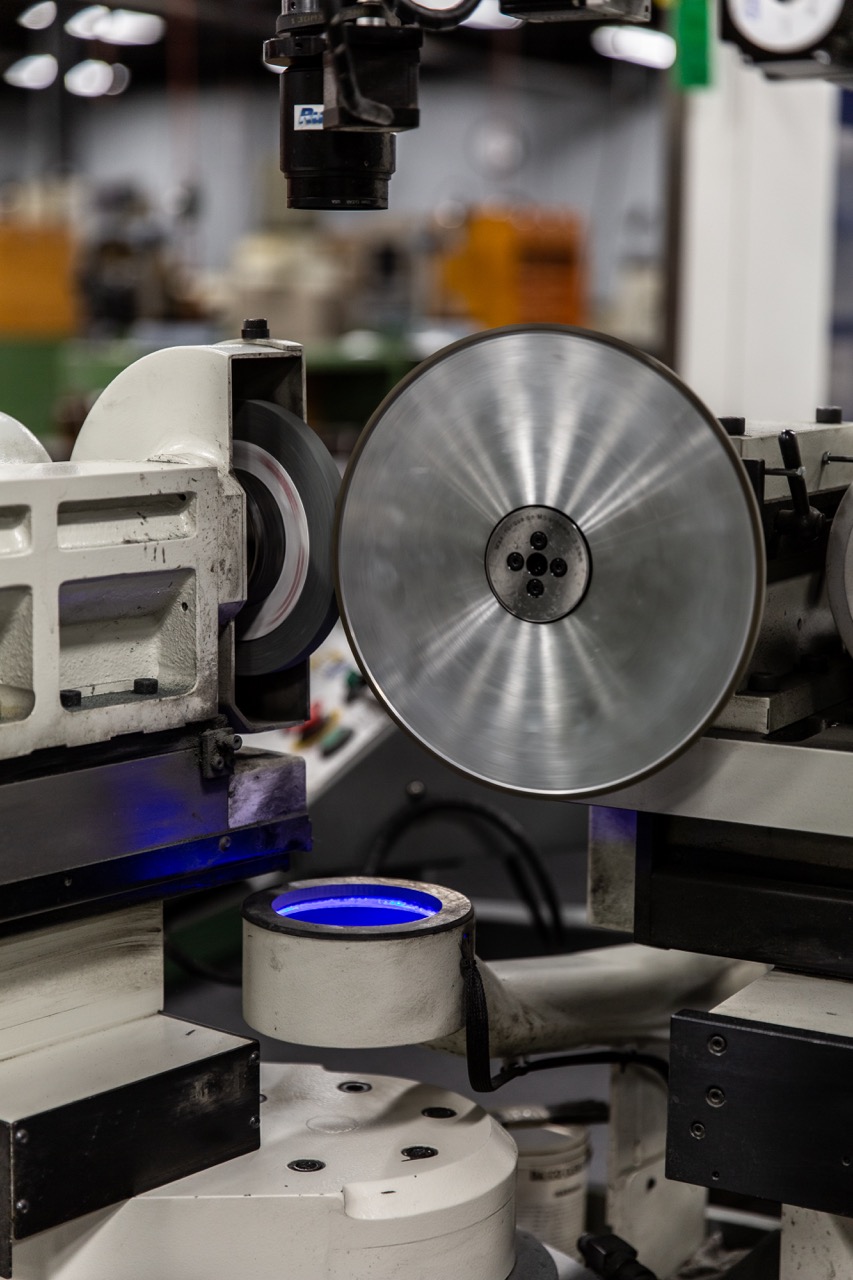

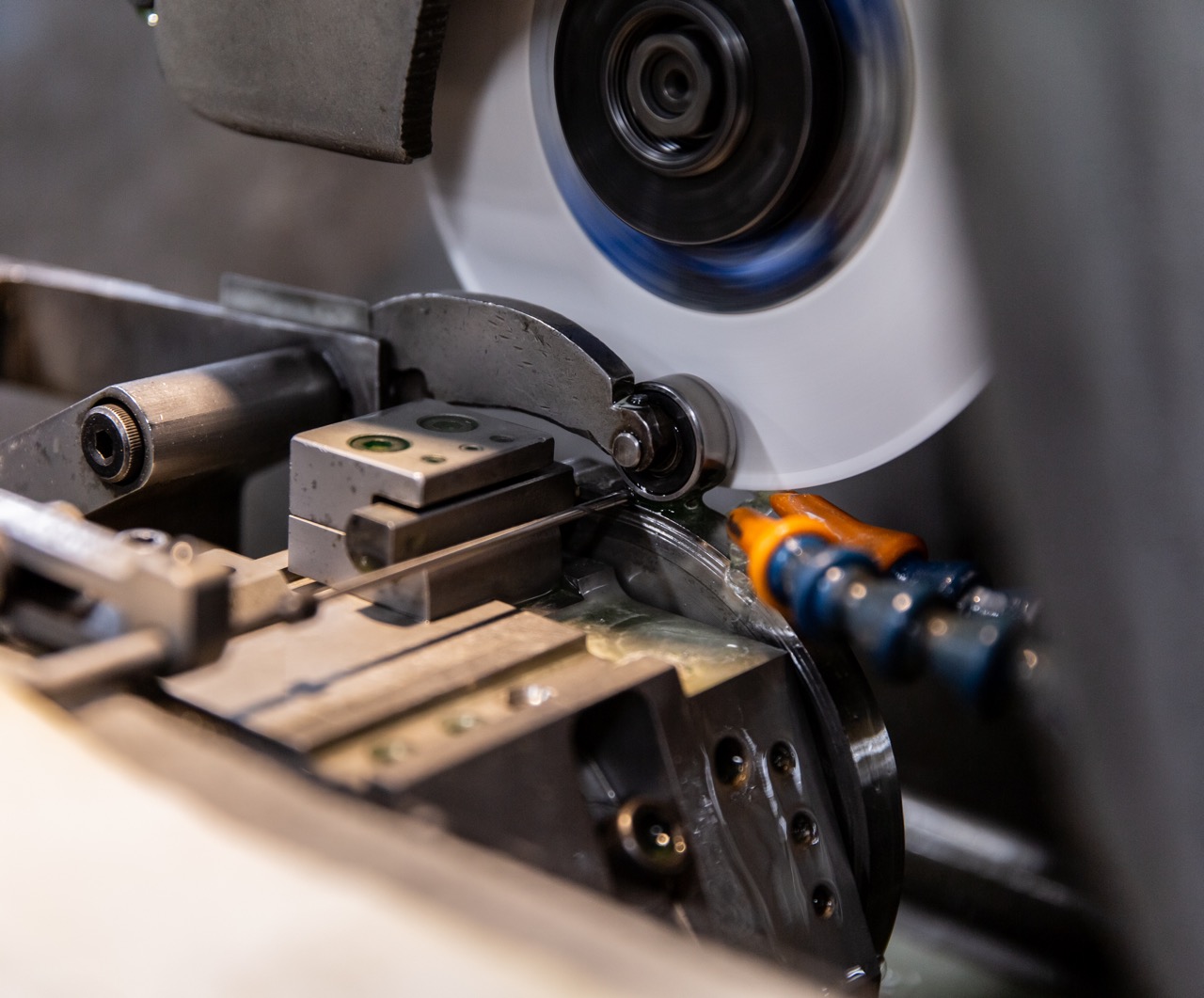

Precision Grinding

CNC Grinding

- Complex & Unique Form Grinding

- Option To Grind with or Without Centers

- Capable of Achieving 8 RMS Precision Ground Surface Finish

- Part Length up to 13″

- Concentricity to 0.0002, Tolerances to 0.0002

- Integrated Robots for Lights Out Operation

CNC Jig Grinding

- Small Precision Ground I.D.’s & Forms

- Part Length up to 3″

- Capable of Achieving 4 RMS Precision Ground Surface Finish

- Custom Work Holding for Precision I.D to O.D. Accuracy

- Concentricity to 0.0002, Tolerances to 0.0002

- Flood Coolant for Improved Surface Finish

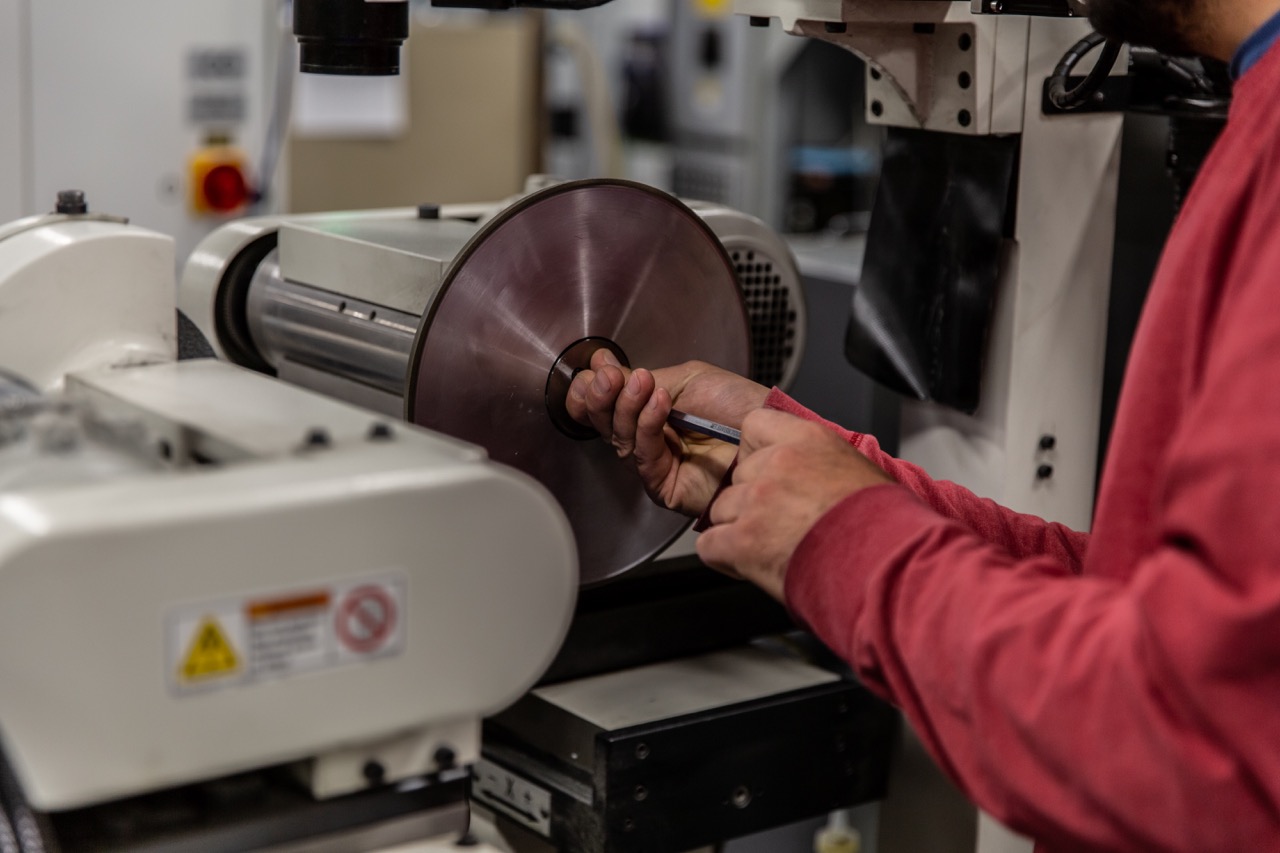

Centerless Grinding

- Up to 15” Grind Wheel Face

- Capable of Achieving 4 RMS Precision Ground Surface Finish

- Simultaneous Grind of Multiple Diameters (Plunge)

- Concentricity to 0.0002, Tolerances to 0.0002

- Integrated Robots for Lights Out Operation

CNC Surface Grinding

- Multiple Machines with Up To 16” x 32” Magnetic Chuck Size

- Capable of Achieving 8 RMS Precision Ground Surface Finish

- Tolerances to 0.0002

- Automatic Grind Wheel Dressing with Size Comp.

- Custom Form Grind & CBN Wheel Options Are Available

Explore our Producto Partner Solutions:

Precision Tooling

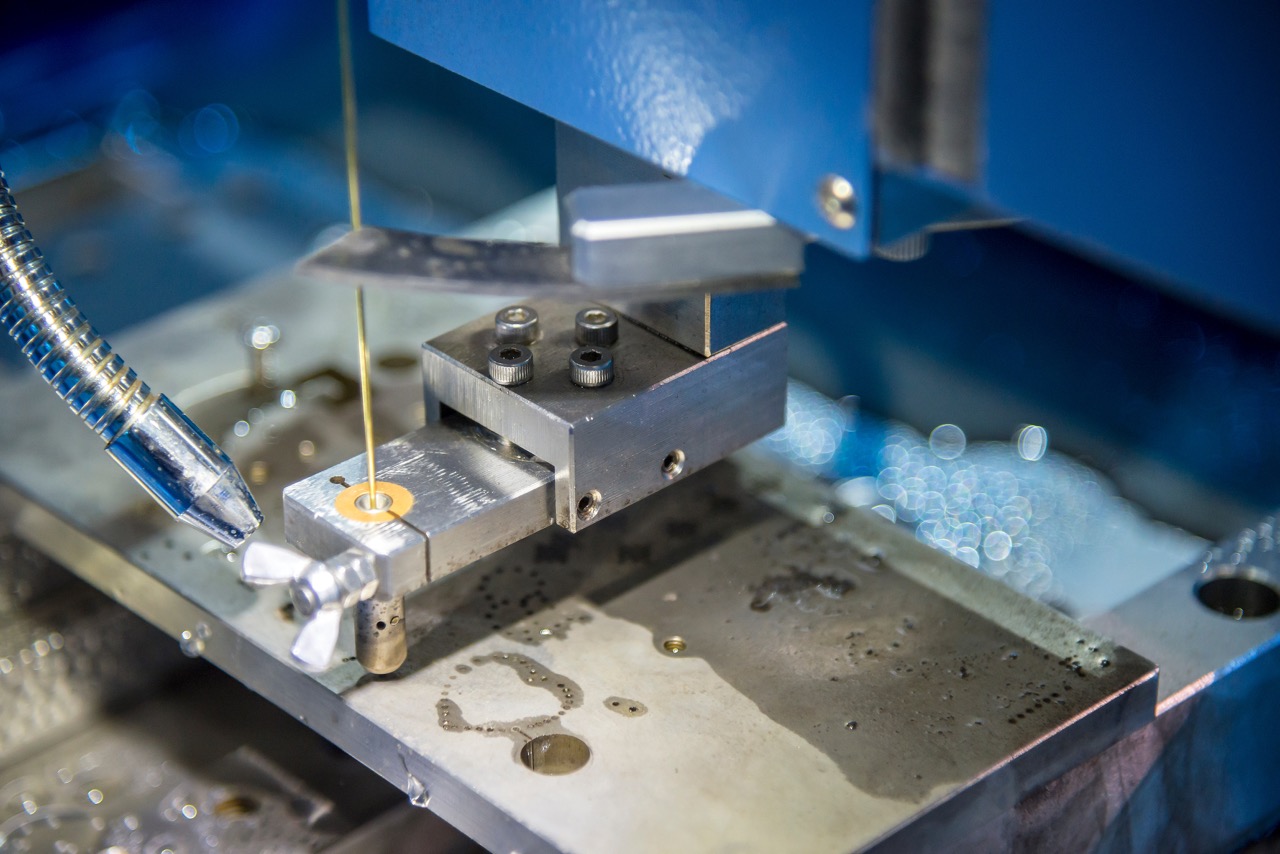

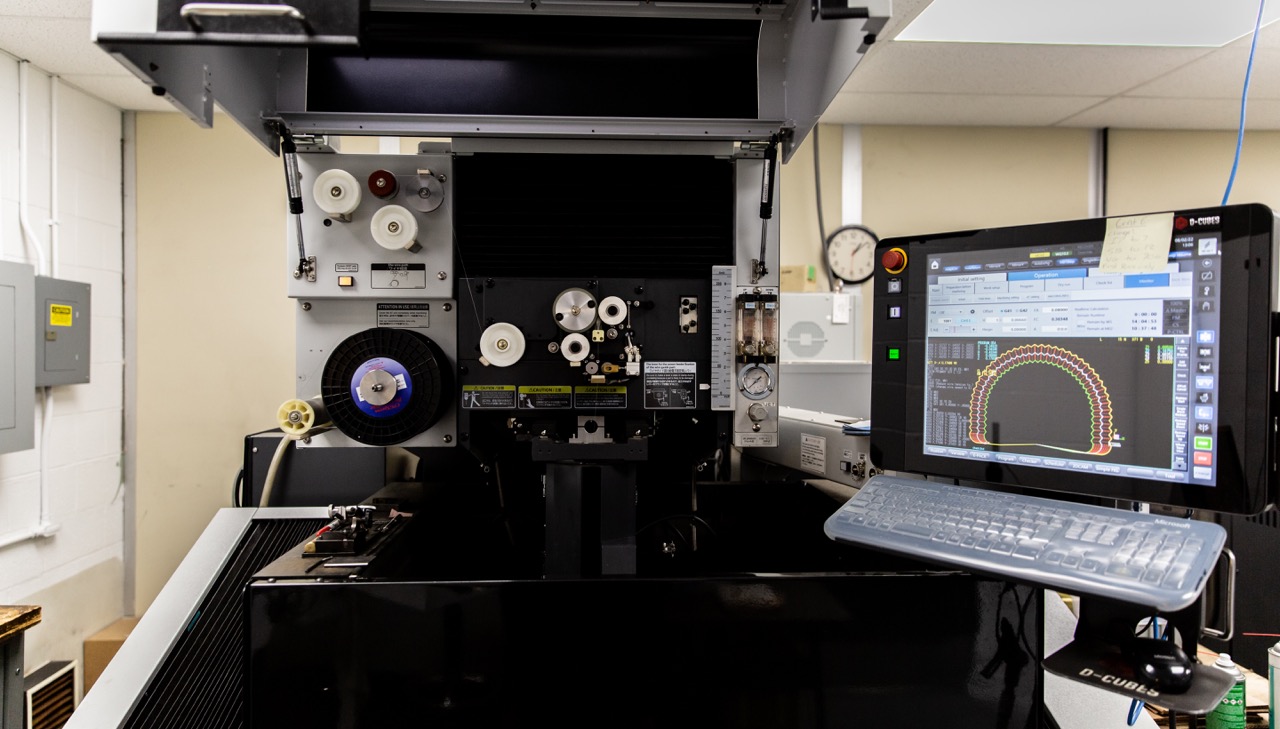

EDM Machining

Wire EDM

- Generate Complex Unique Geometries

- Part Thickness Up To 11″

- Component Precision to 0.0002, Repeatability to 0.0001

- Lights Out Operation

Sinker/ RAM EDM

- In-House Electrode Manufacturing

- Complex Cavity Geometry for Injection Molding Applications

- 18-21 VDI Standard EDM Surface Finish

- Concentricity to 0.0003, Tolerances to 0.0002

- Integrated Robots for Lights Out Operation

EDM Drill

- Part Length up to 13″

- Concentricity to 0.002, Tolerances to 0.003

- 16 VDI Standard EDM Surface Finish

Explore our Producto Partner Solutions:

Precision Tooling

Gun Drilling

- Deep Hole Drilling Utilizing High Pressure Coolant

- Drill Diameters up to 0.625 and 18″ Length

- Concentricity to 0.002, Tolerance to 0.002

Explore our Producto Partner Solutions:

Precision Tooling

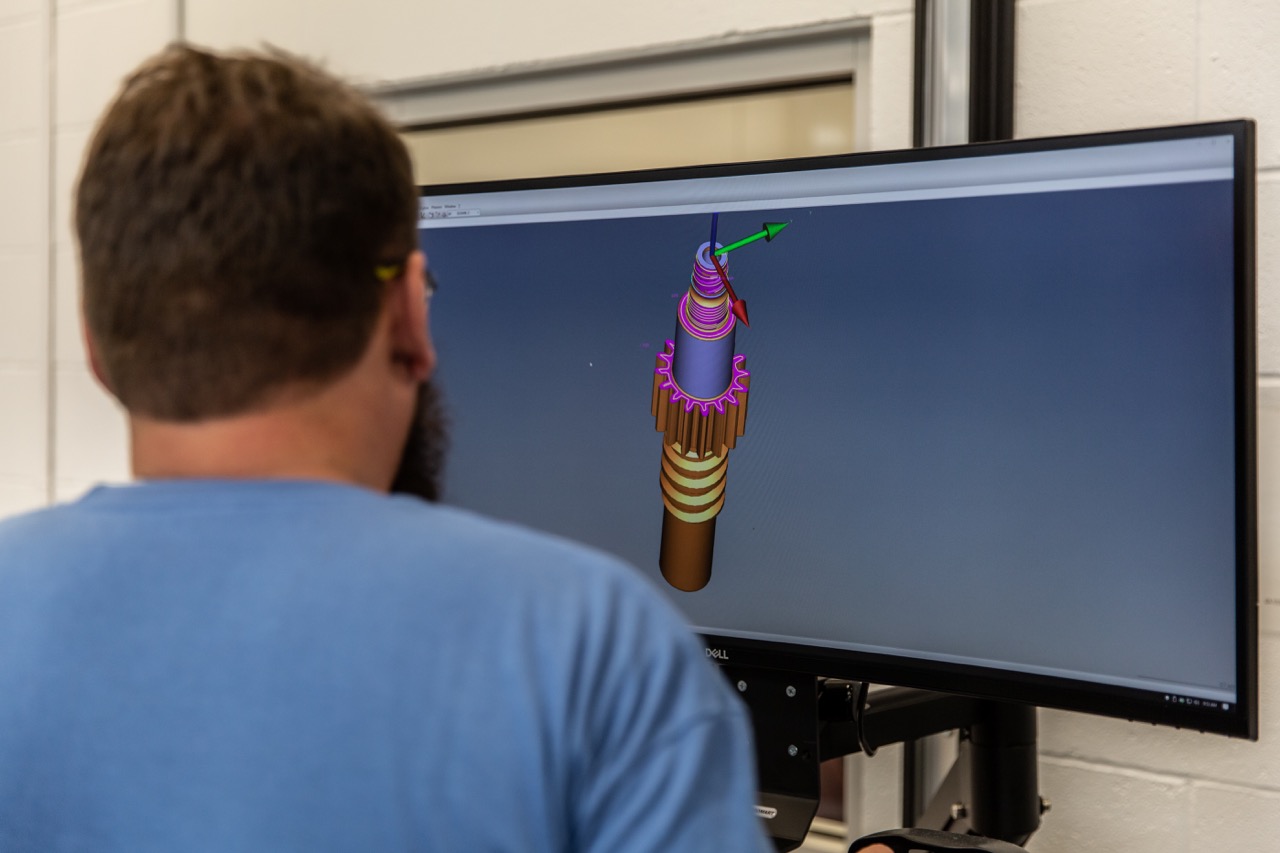

Reverse Engineering

At The Producto Group, we partner with our customers to aid you in the sourcing of difficult to procure components and assemblies. We offer reverse engineering services to our clients in a variety of industries. Our capabilities enable us to analyze, measure and draft your most difficult components. Our in-house engineering department has the tools to create solid models and fully dimensioned product drawings. Our complete offering can help you achieve success from concept, to prototype, to production.

Explore our Producto Partner Solutions:

Precision Tooling

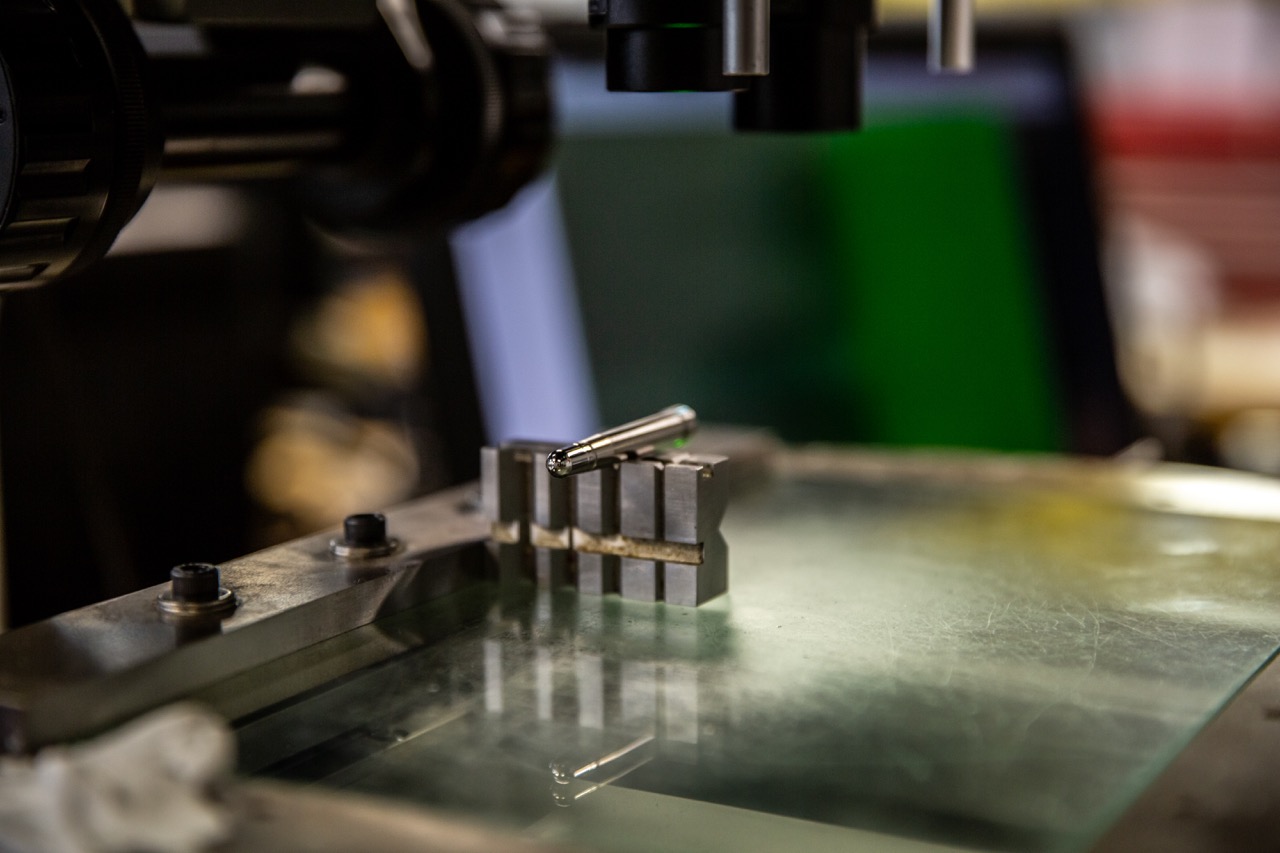

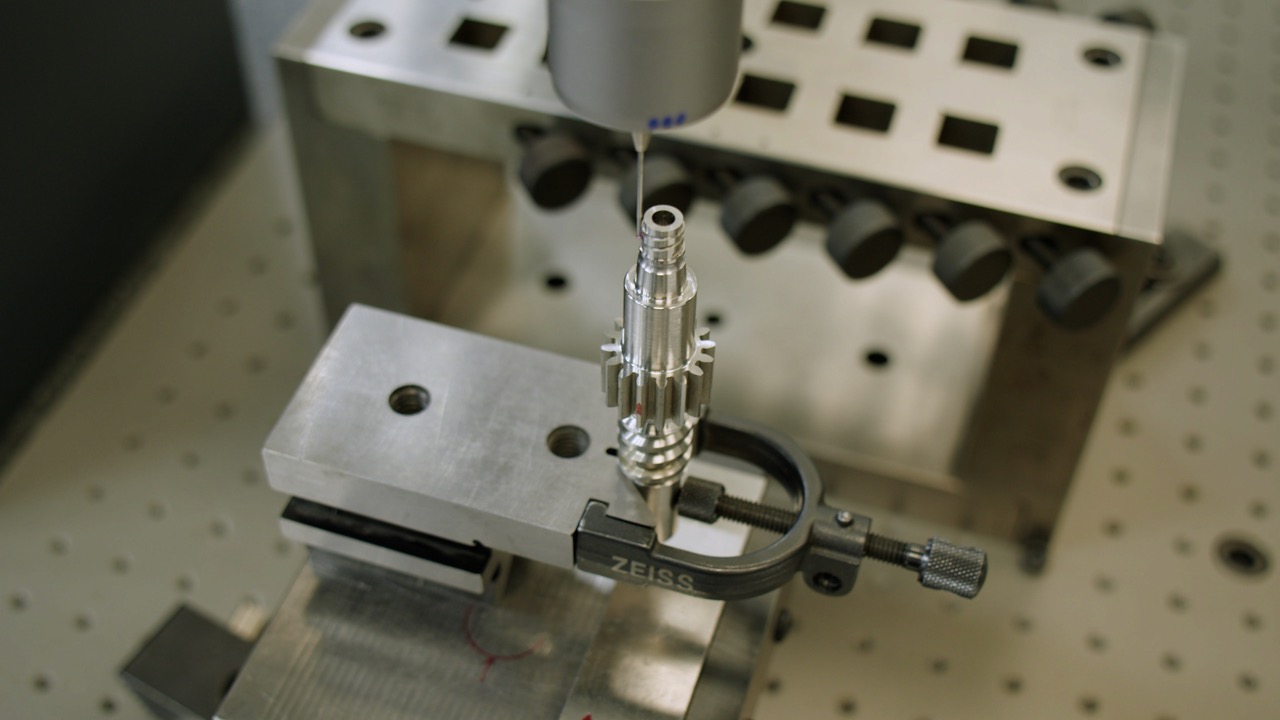

Quality & Metrology

Metrology & Inspection

- Inspection Equipment Accuracy Maintained via Scheduled Calibration

- Inspection Reports

- Material Certification

- Heat Treat Data

- Other customized inspection reports tailored to your specific available upon request

Value Added Services

-

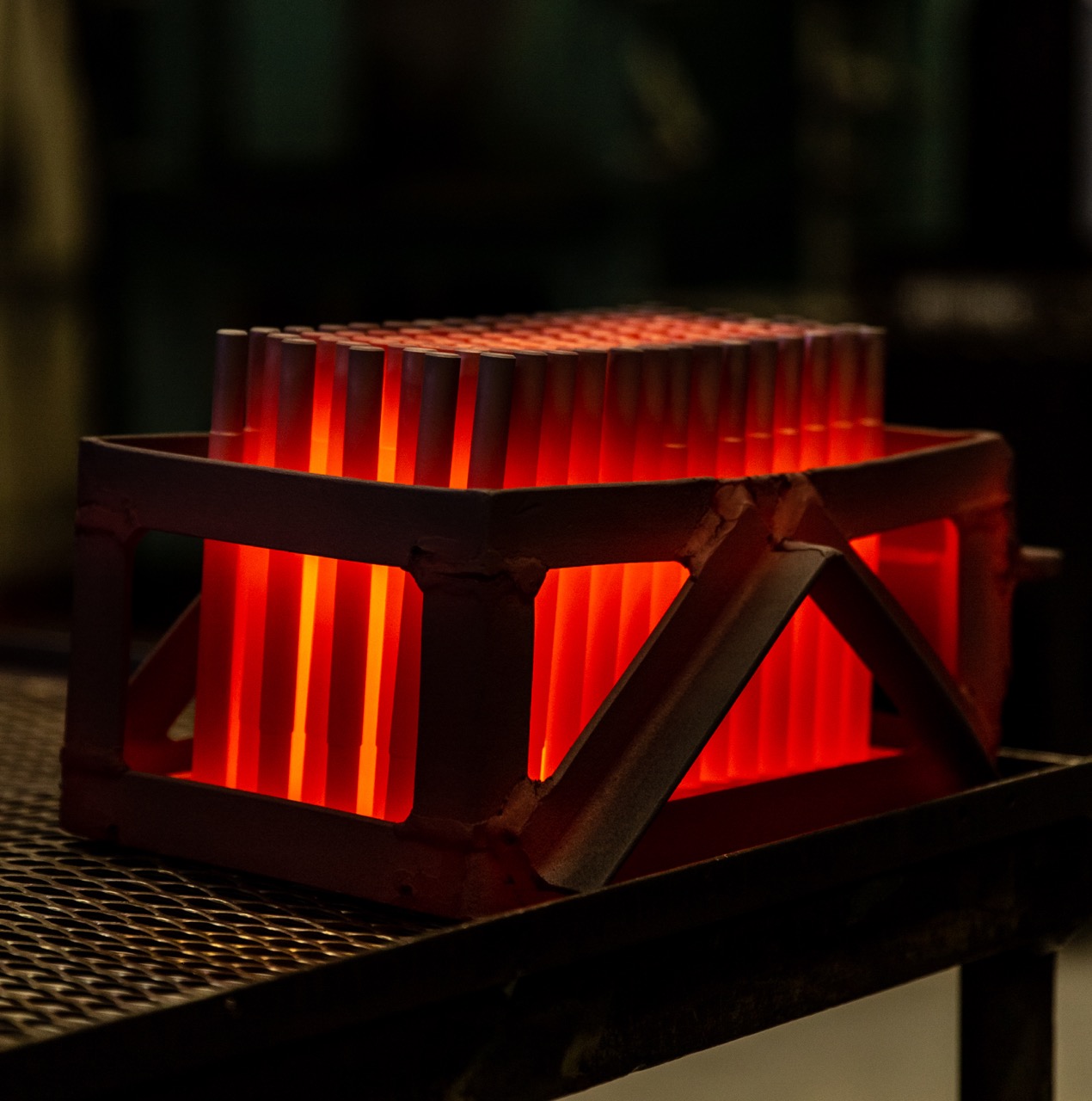

- Heat Treating of All Materials

- Internal Heat Treated and Annealed Using the Latest Technology to Gain Performance Benefits for all our Customers’ Unique Applications

- In-House Heat Treatment

- Oil Quench & Air Quench Options

- Nitrogen Freeze @ Tempering Phase of Heat Treatment

- RC/Hardness Documentation Upon Request

- Laser Engraving

- Part # Engraving for Identification

- Part Serialization Inspection Documentation / Traceability

- Reverse Laser Engraving for Injection Mold Cavity Identification

- Applications Include:

- Brand Identification

- Lot and Date Coding

- Part Identification and Serialized Components

- Mold Cavity, Core, and Pin Engraving

- Instrument Panels

- Finishing/Polishing

- Part Straightening

- Heat Treating of All Materials

For more information about our range of manufacturing value-added capabilities and finishing services, please contact us today.

Explore our Producto Partner Solutions:

Precision Tooling

Materials of Construction

The Producto Group has the expertise to work with a wide range of materials including all metal alloys, ultra-hard tool steels and super alloys.

- 300 SERIES STAINLESS

- 400 SERIES STAINLESS

- LOW CARBON STEELS

- H-13

- S-7

- A-2

- D-2

- M-2

- PM-M4

- A-11

- ALUMINUM – 6000/7000

- MOLDMAX HIGH HARD

- MOLDSTAR

- Other materials available

Don’t see what you’re looking for? Contact Us today! The Producto Group has a multitude of experience working with, shaping, and forming different types of materials.